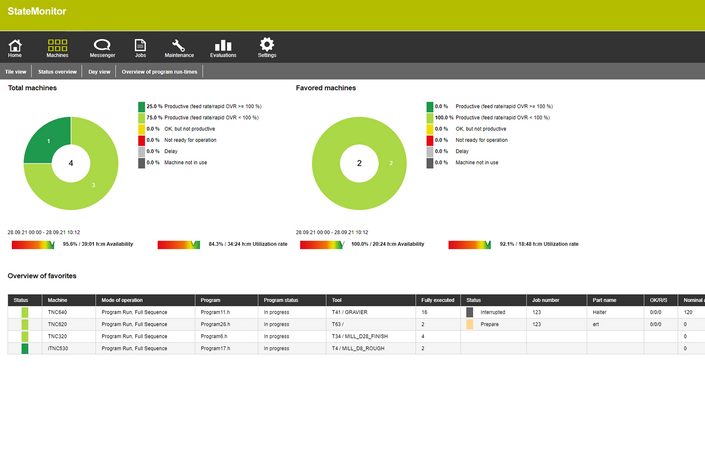

Record, evaluate and visualize machine data with the StateMonitor software

How can I improve my manufacturing throughput? How can I keep an overview while operating multiple machines? Would investing in a new machine tool be worthwhile? StateMonitor helps you make decisions about production optimization.

Machine downtime

10 minutes of undetected machine downtime per shift with five machines in three-shift operation over 264 days at an hourly rate of €80, with a cost of €52,800 per year.

Spindle hours

You get an additional 3168 hours out of your spindle if the productive machine time is increased by 15% when operating five machines in two shifts.

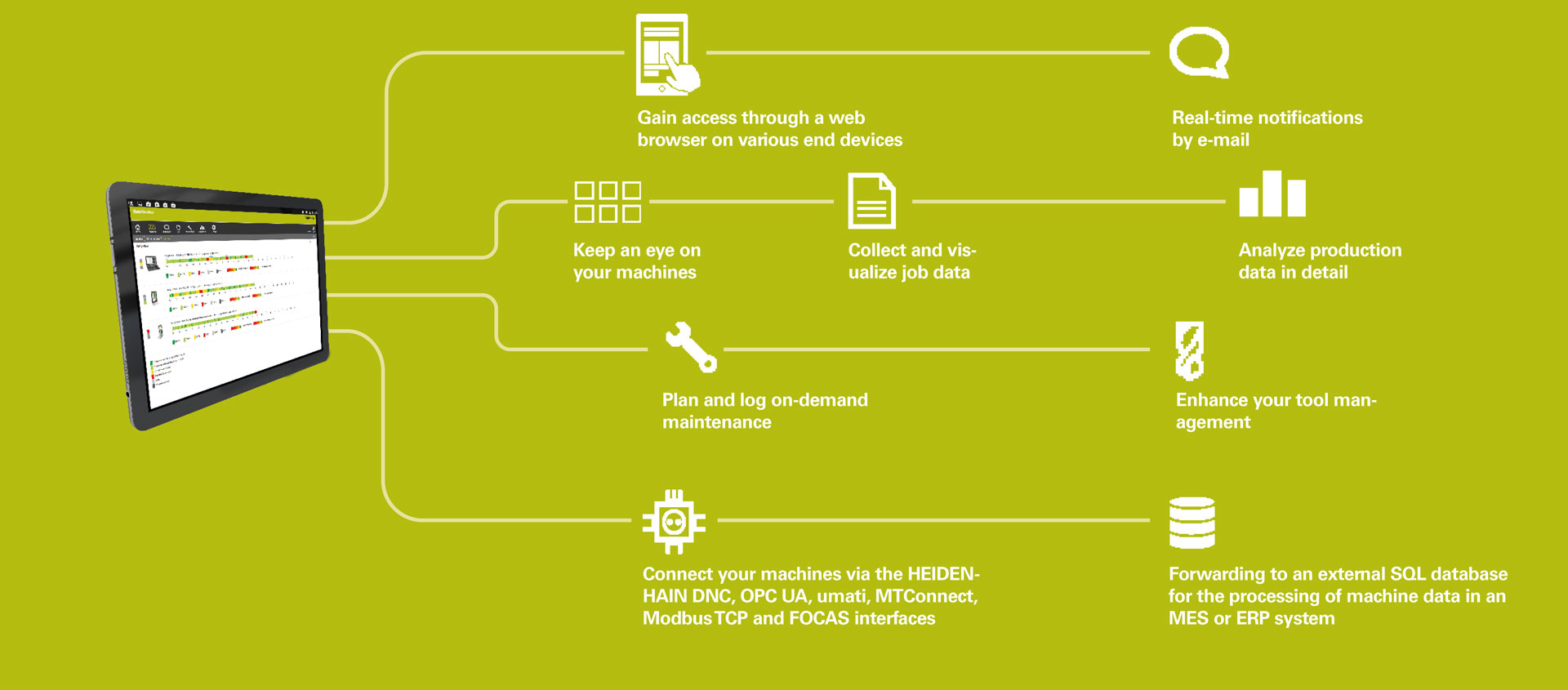

Interfaces

When connecting your machines to StateMonitor, you can choose from between four different interfaces: HEIDENHAIN DNC, OPC UA, MTConnect or Modbus TCP. Connecting via HEIDENHAIN DNC takes only 3 minutes if your machine can be reached over the network.