Website for machine experts

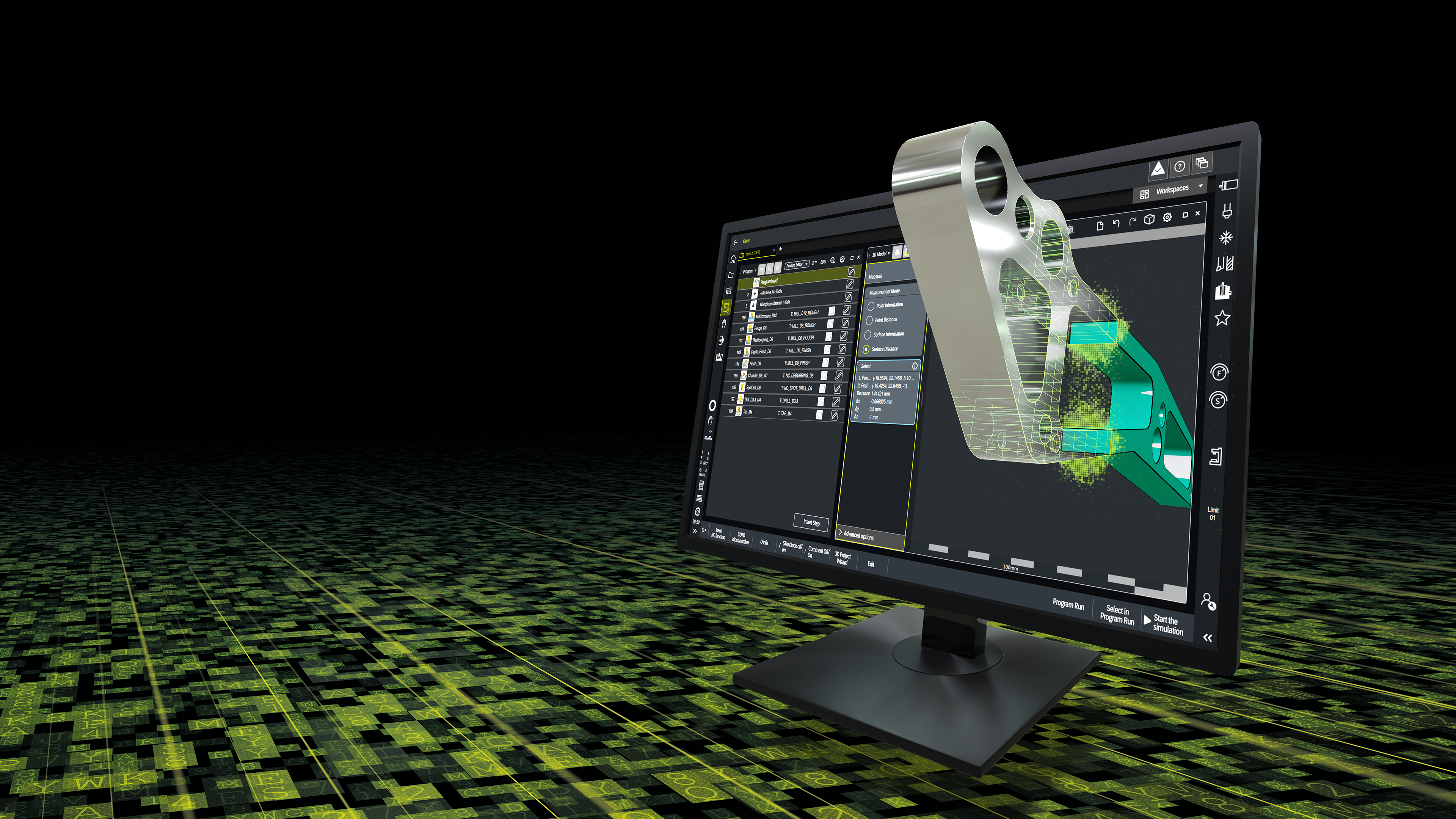

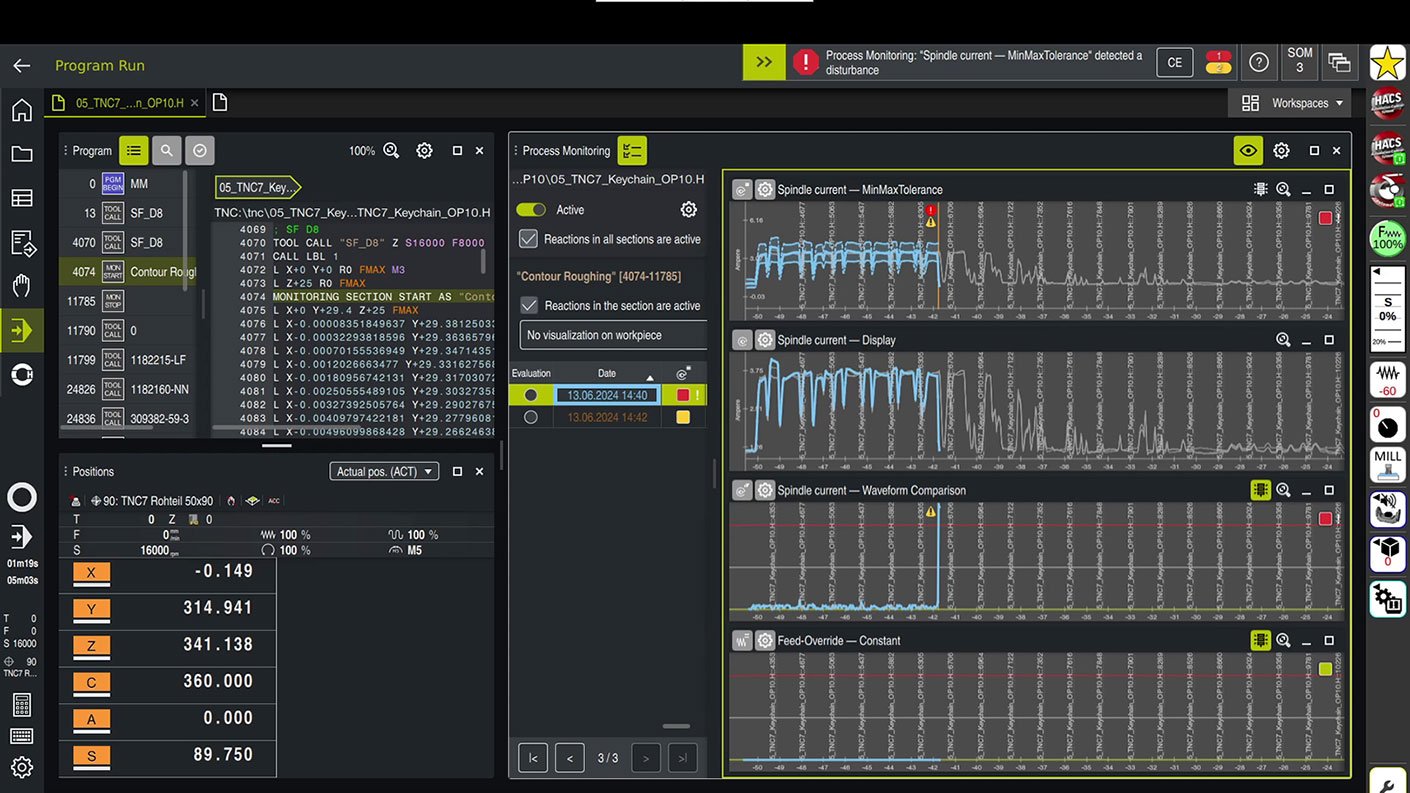

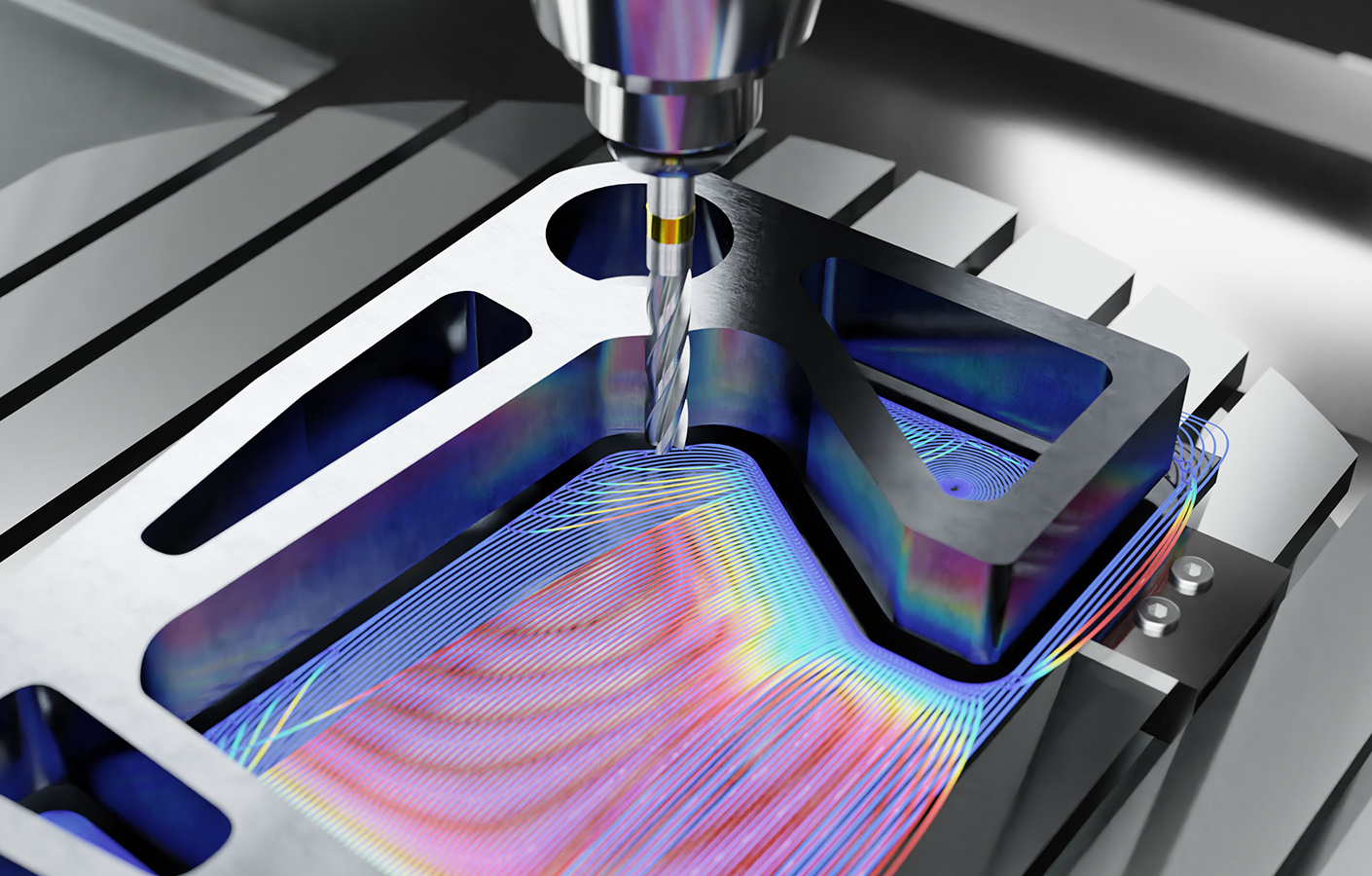

Empower Manufacturing

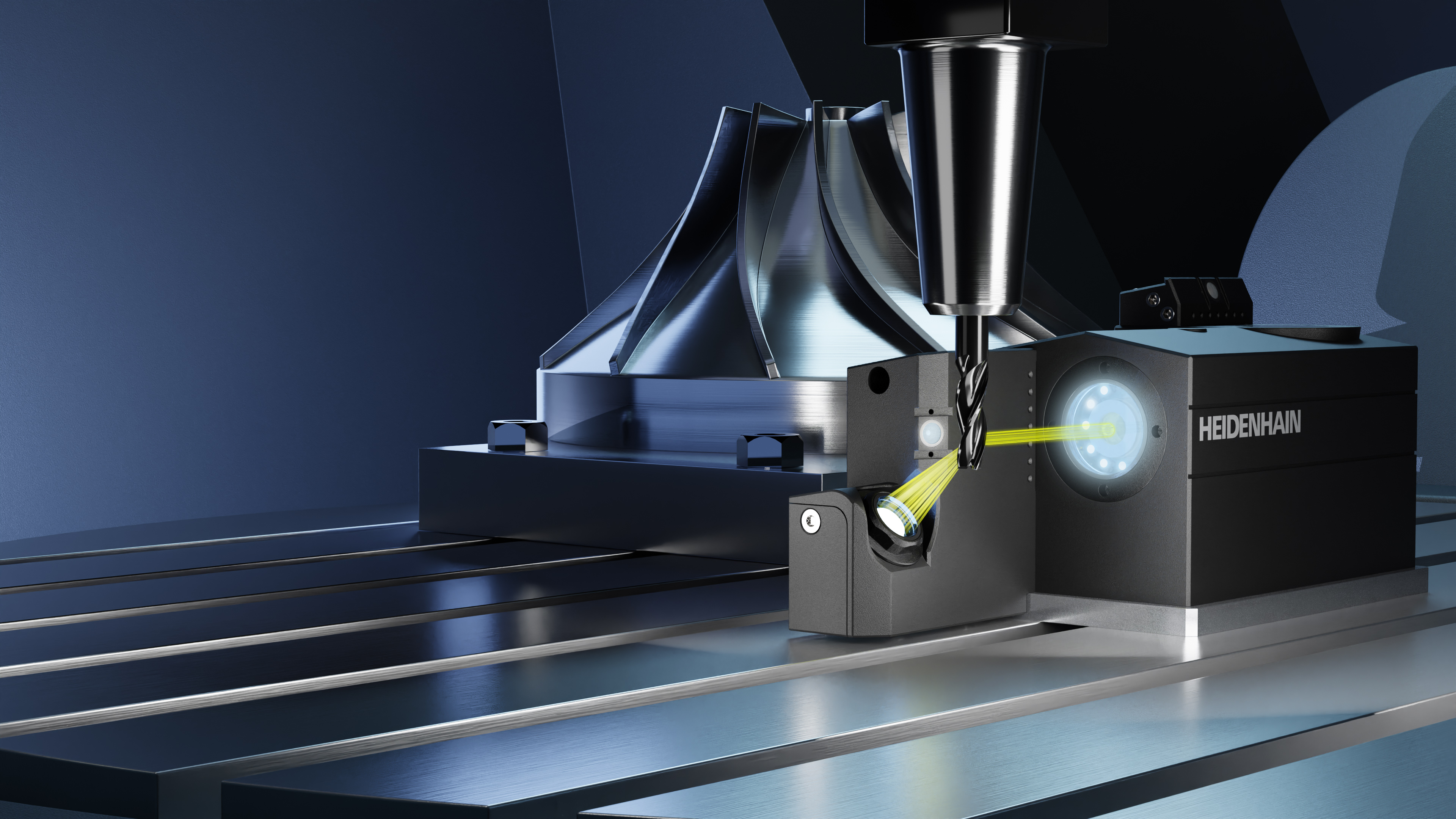

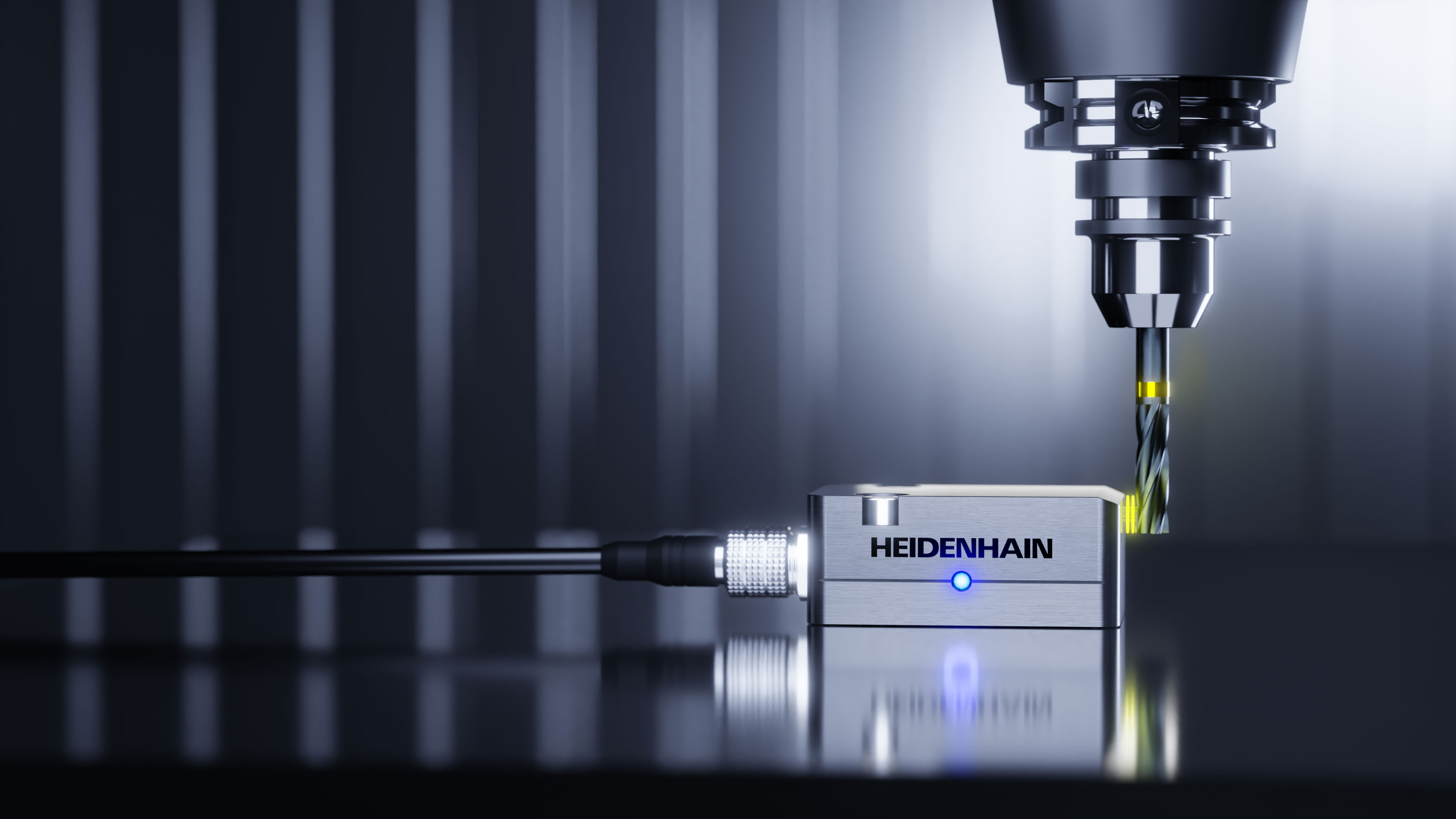

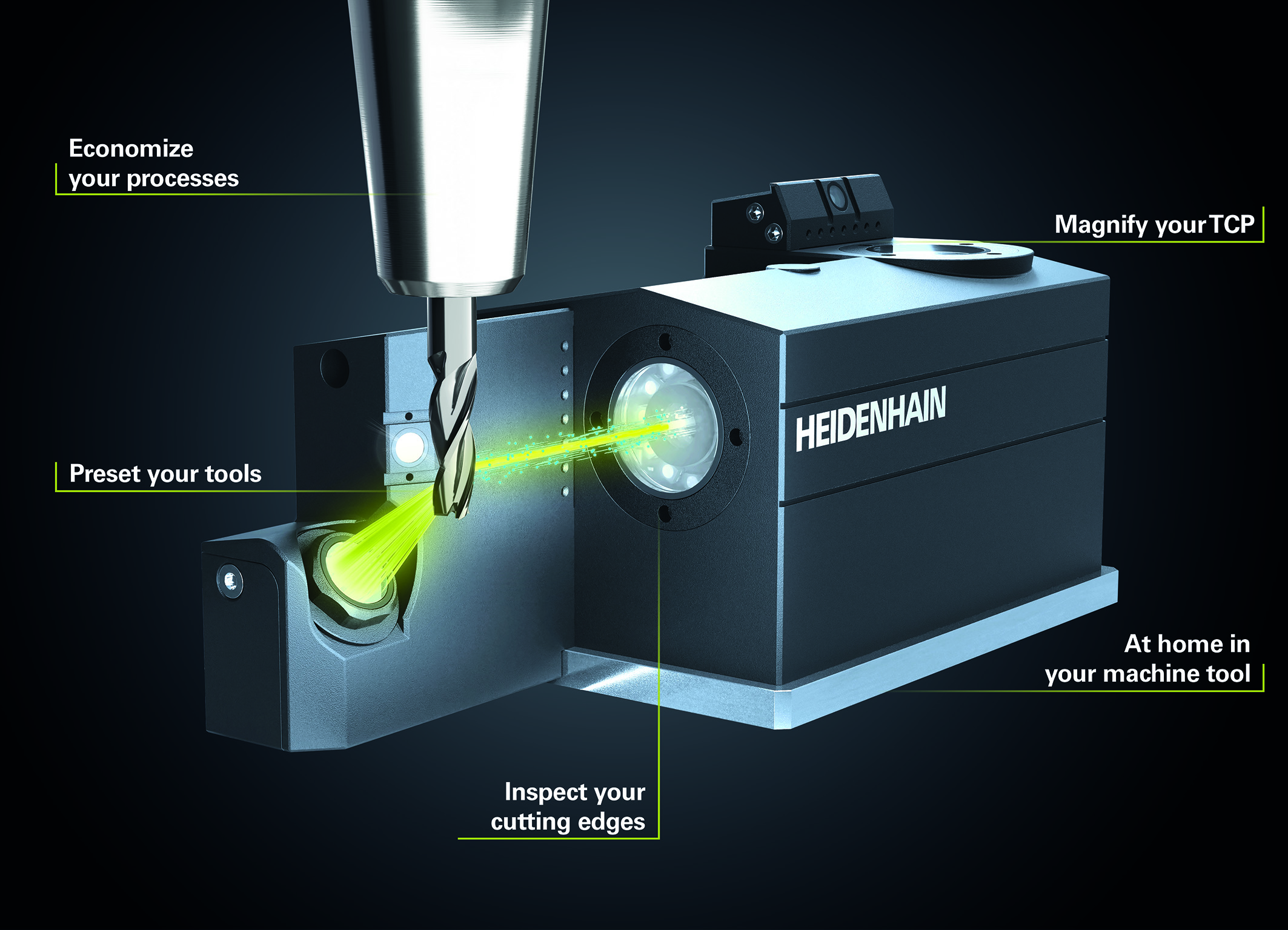

Intelligent system solutions for machine tools and automated manufacturing processes

Experience exceptional accuracy, reliability and performance through rigorously engineered systems and seamlessly integrated components from the HEIDENHAIN GROUP.

Partner with us to make your manufacturing more efficient, agile and future-ready.