Website for machine experts

Collect, evaluate and visualize machine data with the StateMonitor software

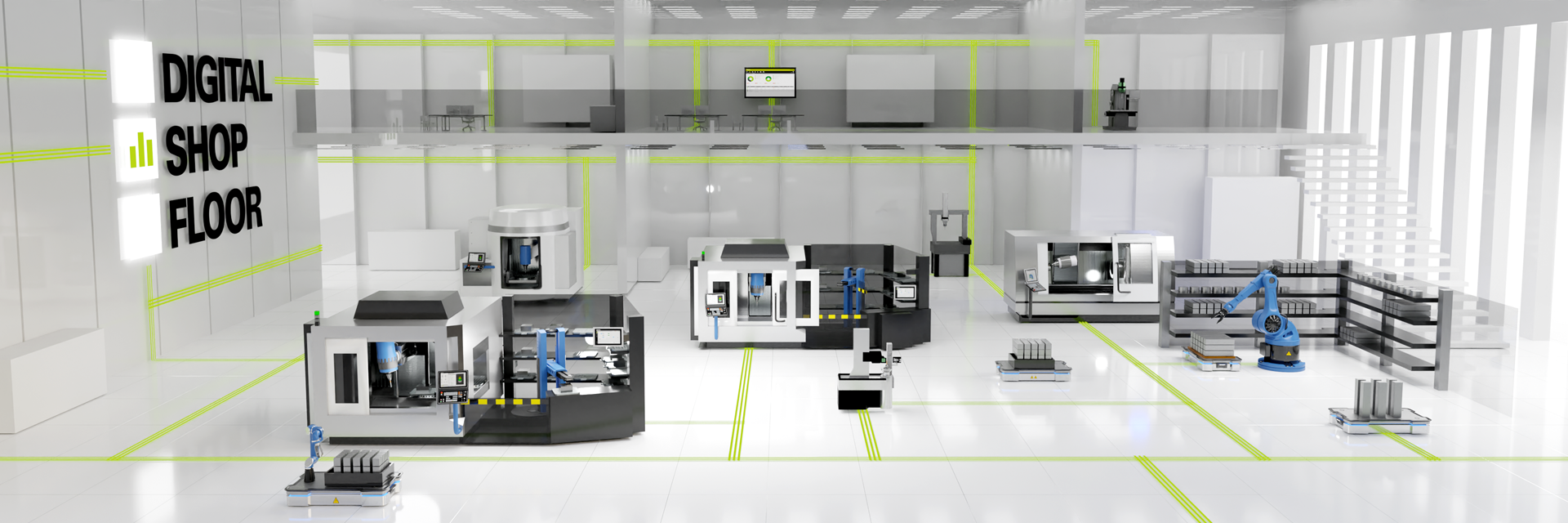

How can I improve shopfloor throughput? How can I manage multiple machines? Should I invest in a new machine tool? StateMonitor gives you the insights needed for informed decisions. Version 1.6.0 now also offers energy monitoring capability.

Programming stations for lathe and milling controls

The programming station reduces machine idle time by allowing programs to be created, tested and optimized away from the machine. Its keyboard is based on the machine's keyboad, thereby ensuring a short learning curve.